Introduction

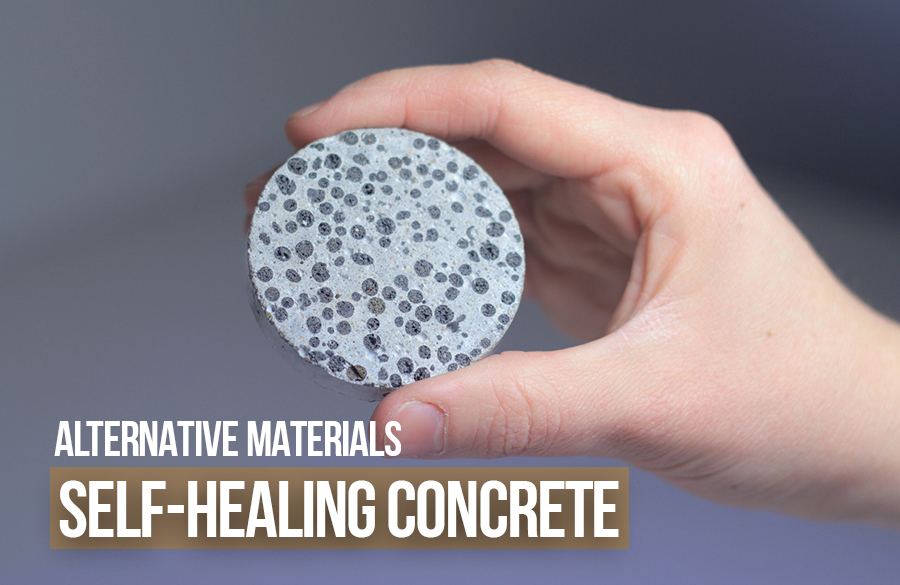

In the realm of construction and infrastructure development, durability and longevity are paramount. Concrete, the most widely used construction material globally, often faces challenges such as cracking due to various factors like loading, shrinkage, and environmental stresses. Traditional concrete repairs are costly, time-consuming, and may lead to further deterioration over time. However, a groundbreaking innovation is reshaping the future of infrastructure: self-healing concrete. This blog explores the evolution, mechanisms, applications, and potential of self-healing concrete in revolutionizing the sustainability of our built environment.

The Evolution of Self-Healing Concrete

The concept of self-healing concrete finds its roots in nature, where organisms exhibit remarkable abilities to repair and regenerate. Inspired by this, researchers embarked on a journey to develop concrete with inherent self-healing capabilities. The early 2000s witnessed pioneering research in this domain, laying the foundation for subsequent advancements.

Mechanisms of Self-Healing Concrete

Self-healing concrete employs various mechanisms to repair cracks autonomously. One approach involves the use of microbial agents embedded within the concrete matrix. These microorganisms remain dormant until activated by the presence of water infiltrating through cracks. Upon activation, they produce calcium carbonate, effectively sealing the cracks and restoring the concrete’s integrity.

Another method relies on encapsulated healing agents dispersed throughout the concrete. When cracks form, these capsules rupture, releasing healing agents such as epoxy or polyurethane into the fissures, thereby sealing them. Autogenous healing, wherein unhydrated cement particles react with water to form calcium carbonate, and fiber-based healing, utilizing shape memory polymers or microfibers to bridge cracks, are additional mechanisms employed in self-healing concrete.

Self-healing concrete is a innovative type of concrete that has the ability to repair cracks that occur due to various factors such as loading, shrinkage, or environmental conditions. The concept behind self-healing concrete is inspired by biological systems, where the material is designed to mimic the natural healing process observed in living organisms.

There are several approaches to achieving self-healing properties in concrete:

- Microbial Healing: This method involves incorporating bacterial spores and a calcium-rich nutrient into the concrete mix. When cracks form and water penetrate the concrete, the spores germinate and produce limestone, effectively sealing the crack.

- Capsule-Based Healing: Microcapsules containing a healing agent such as epoxy or polyurethane are embedded in the concrete mix. When cracks develop, these capsules rupture, releasing the healing agent into the crack to seal it.

- Autogenous Healing: This approach relies on the presence of unhydrated cement particles in the concrete mix. When cracks form, water enters and reacts with these particles, producing calcium carbonate which fills the crack and restores the concrete’s integrity.

- Fiber-Based Healing: Fibers such as shape memory polymers or microfibers are incorporated into the concrete mix. When cracks occur, these fibers help to bridge the gap and prevent further propagation of the crack.

Self-healing concrete offers several potential benefits, including increased durability, reduced maintenance costs, and longer service life for concrete structures. However, there are still challenges to overcome, such as scalability, cost-effectiveness, and ensuring consistent performance in different environmental conditions. Ongoing research and development in this field aim to address these challenges and further improve the effectiveness of self-healing concrete technologies.

Applications of Self-Healing Concrete

The applications of self-healing concrete are diverse, spanning from infrastructure projects to residential and commercial constructions. In transportation infrastructure, such as bridges and roads, where durability is critical, self-healing concrete can mitigate the effects of wear and tear, reducing maintenance costs and prolonging service life. Similarly, in buildings and structures prone to cracking, such as dams and tunnels, self-healing concrete offers enhanced durability and resilience against environmental stresses.

Self-healing concrete offers a wide range of applications across various sectors of construction and infrastructure development. Its unique ability to autonomously repair cracks and mitigate deterioration makes it particularly suitable for environments where durability, longevity, and maintenance efficiency are crucial. Here are some key applications of self-healing concrete:

- Transportation Infrastructure:

Bridges: Bridges are exposed to harsh environmental conditions and heavy traffic loads, leading to cracks and structural deterioration over time. Self-healing concrete can significantly enhance the durability and service life of bridge structures by repairing cracks and preventing further degradation caused by moisture ingress and corrosion of reinforcing steel.

Roads and Highways: Self-healing concrete can be used in the construction of roads and highways to mitigate cracking caused by thermal cycling, traffic loads, and freeze-thaw cycles. By reducing the formation of cracks and minimizing water infiltration, self-healing concrete helps maintain the integrity of road surfaces, extending their lifespan and reducing maintenance requirements.

- Buildings and Structures:

Residential and Commercial Construction: In residential and commercial buildings, self-healing concrete can be utilized to improve the durability and aesthetic appeal of concrete floors, walls, and other structural elements. By minimizing the formation and propagation of cracks, self-healing concrete helps preserve the structural integrity and appearance of buildings, reducing the need for frequent repairs and maintenance.

Tunnels and Underground Structures: Tunnels and underground structures are susceptible to cracking and water infiltration, which can compromise their structural stability and safety. Self-healing concrete can be applied in the construction of tunnel linings, underground parking garages, and other subterranean structures to prevent water ingress, mitigate cracking, and enhance long-term durability.

- Marine and Coastal Structures:

Sea Walls and Breakwaters: Marine and coastal structures are constantly exposed to corrosive saltwater, wave action, and marine organisms, leading to deterioration and structural damage. Self-healing concrete can be used to reinforce sea walls, breakwaters, and other coastal structures, providing enhanced protection against erosion, cracking, and degradation caused by saltwater exposure.

Port Infrastructure: Ports and harbors require durable and resilient infrastructure to withstand the dynamic forces exerted by ships, cargo handling equipment, and harsh marine environments. Self-healing concrete can be employed in the construction of quay walls, jetties, and other port infrastructure to improve resistance to cracking, abrasion, and corrosion, thereby extending the service life of these vital facilities.

- Water Infrastructure:

Dams and Reservoirs: Dams and reservoirs play a critical role in water resource management, flood control, and hydroelectric power generation. Self-healing concrete can be utilized in the construction and repair of dam structures to enhance their resistance to cracking, seepage, and degradation caused by water pressure and environmental factors.

Water Treatment Facilities: Water treatment facilities, including water storage tanks, pipelines, and treatment plants, require durable and corrosion-resistant infrastructure to ensure the safe and reliable supply of clean water. Self-healing concrete can be applied in the construction of water storage tanks and pipelines to prevent leakage, mitigate corrosion, and maintain structural integrity over time.

- Industrial Facilities:

Industrial Floors and Pavements: Industrial facilities such as manufacturing plants, warehouses, and distribution centers require durable and wear-resistant flooring solutions to withstand heavy machinery, vehicular traffic, and abrasive materials. Self-healing concrete can be used to construct industrial floors and pavements that exhibit enhanced resistance to cracking, abrasion, and surface wear, reducing maintenance costs and downtime.

- Critical Infrastructure:

Nuclear Facilities: Nuclear power plants and other critical infrastructure require robust and resilient construction materials to ensure safety and reliability. Self-healing concrete can be employed in the construction of containment structures, reactor buildings, and other critical components to enhance resistance to cracking, radiation exposure, and environmental degradation, thereby improving the long-term performance and safety of nuclear facilities.

In summary, self-healing concrete offers diverse applications across various sectors of construction and infrastructure development, ranging from transportation and buildings to marine, water, industrial, and critical infrastructure. By providing autonomous crack repair and enhanced durability, self-healing concrete contributes to the creation of resilient, sustainable, and long-lasting built environments that meet the evolving needs of modern society.

Advantages of Self-Healing Concrete

The adoption of self-healing concrete presents several advantages over traditional concrete:

- Durability:Self-healing concrete enhances the durability of structures by autonomously repairing cracks, thereby preventing further deterioration.

- Cost-Effectiveness:While initial implementation costs may be higher, the long-term cost savings in maintenance and repair outweigh the initial investment.

- Sustainability:By extending the service life of structures, self-healing concrete contributes to sustainability by reducing the need for frequent repairs and replacements, thus conserving resources.

- Safety:Improved structural integrity and reduced risk of failure enhance safety for occupants and users of infrastructure.

Challenges and Future Directions

Despite its promise, self-healing concrete faces several challenges that warrant further research and development. These include scalability of production, compatibility with existing construction practices, long-term performance under varying environmental conditions, and cost-effectiveness. Addressing these challenges will be crucial in realizing the full potential of self-healing concrete and facilitating its widespread adoption in the construction industry.

While self-healing concrete holds immense promise for revolutionizing the construction industry, several challenges must be addressed to realize its full potential. Additionally, future research directions can further enhance its effectiveness and widespread adoption. Here are some key challenges and future directions for self-healing concrete:

Challenges:

- Scalability and Production Cost:One of the primary challenges facing self-healing concrete is the scalability of production and its associated cost. Incorporating self-healing agents such as bacteria, encapsulated healing agents, or fibers can increase the material cost, making it less economically viable for large-scale applications.

- Long-Term Performance:Ensuring the long-term performance and reliability of self-healing concrete under various environmental conditions remains a significant challenge. Factors such as exposure to freeze-thaw cycles, chemical aggressors, and UV radiation can affect the effectiveness of self-healing mechanisms over time.

- Compatibility and Standardization:Self-healing concrete must be compatible with existing construction practices, including mixing, pouring, and curing procedures. Standardization of self-healing concrete materials and testing protocols is essential to ensure consistency and reliability across different projects and applications.

- Mechanical Properties:The incorporation of self-healing agents or fibers may affect the mechanical properties of concrete, such as compressive strength, flexural strength, and stiffness. Balancing the self-healing capabilities with the structural performance of concrete is crucial to maintaining structural integrity and safety.

Environmental Impact: The environmental impact of self-healing concrete, including the production process, the use of self-healing agents, and end-of-life considerations, must be carefully evaluated. Sustainable sourcing of materials and eco-friendly self-healing agents can mitigate the environmental footprint of self-healing concrete.

Future Directions:

- Advanced Self-Healing Agents:Research into novel self-healing agents with enhanced properties, such as increased activation efficiency, improved compatibility with concrete matrices, and prolonged shelf life, can further enhance the effectiveness of self-healing concrete.

- Nanotechnology and Smart Materials:Integration of nanotechnology and smart materials into self-healing concrete can enable real-time monitoring of cracks and targeted delivery of healing agents, optimizing repair efficiency and reducing material wastage.

- Bioinspired Approaches:Drawing inspiration from natural self-repair mechanisms observed in living organisms, such as plants and animals, can inspire the development of innovative self-healing strategies and materials for concrete.

- Multifunctional Concrete:Exploring the potential of self-healing concrete as a multifunctional material with additional properties, such as self-cleaning, self-sensing, and thermal insulation, can broaden its applications and value proposition in the construction industry.

- Life Cycle Assessment:Conducting comprehensive life cycle assessments (LCAs) to evaluate the environmental, economic, and social impacts of self-healing concrete can inform decision-making and promote sustainable practices in the construction sector.

- Field Trials and Real-World Applications:Conducting field trials and implementing self-healing concrete in real-world construction projects can provide valuable data on its performance, durability, and cost-effectiveness under practical conditions.

In conclusion, addressing the challenges and pursuing future research directions outlined above can accelerate the development and adoption of self-healing concrete as a transformative construction material. By overcoming technical barriers, enhancing performance, and advancing sustainability, self-healing concrete has the potential to revolutionize the way we build and maintain infrastructure, creating resilient and long-lasting built environments for future generations.

Conclusion:

Self-healing concrete represents a remarkable innovation in the field of construction materials, offering a sustainable solution to enhance the durability and longevity of infrastructure. With its ability to autonomously repair cracks and mitigate deterioration, self-healing concrete holds the promise of revolutionizing the way we build and maintain structures. As research and development in this field continue to advance, the widespread adoption of self-healing concrete is poised to reshape the future of infrastructure sustainability, ensuring resilient and long-lasting built environments for generations to come.

Ms. Feba S Thomas

Related Posts

Embracing Nature’s Symphony: A Deep Dive into the Beauty and Importance of the Natural World

Introduction: Nature, with its boundless wonders and captivating beauty, serves as a profound source of inspiration, solace, and sustenance for humanity. In this blog, we

Local self-government

Local self-government Local Government is an integral part of the three-tier system of the government introduced on the recommendation of Balwant Rai Mehta Committee on

Forensic Diatom Analysis: Investigating the Depths of Evidence

Introduction :- Diatoms are a type of single-celled algae, belonging to the group known as Bacillariophyta. They are one of the most common types of