AI for Supply Chain Optimization and Logistics

Uncategorized

Introduction

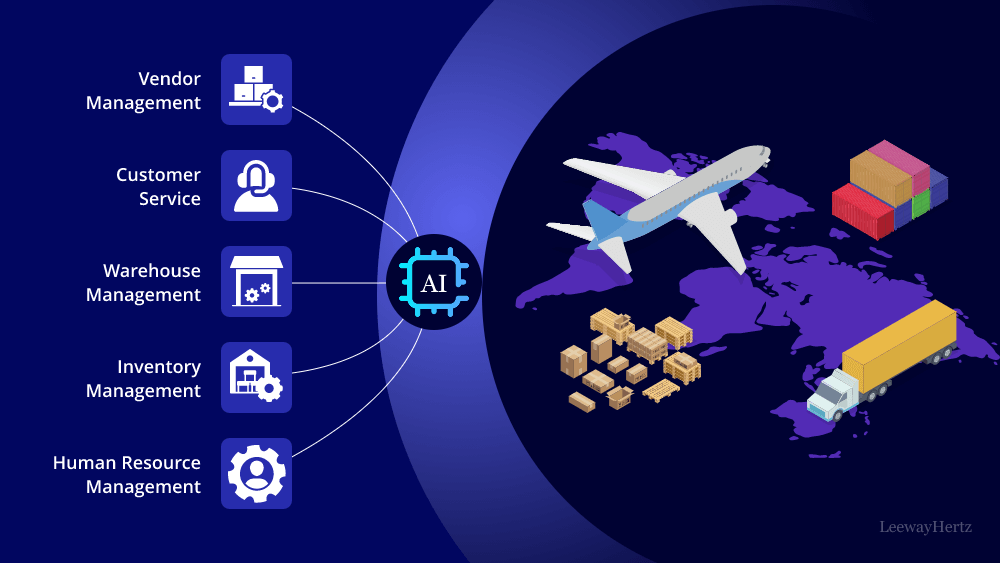

Artificial Intelligence (AI) has emerged as a revolutionary force in reshaping the dynamics of supply chain optimization and logistics. In a globally connected marketplace where consumer expectations continue to rise and disruptions have become a norm, the traditional systems of supply chain management are increasingly insufficient. The growing complexity of supply chains, influenced by diverse factors such as geopolitical tensions, natural disasters, pandemics, fluctuating demand, and digital transformation, has necessitated the adoption of intelligent, adaptive, and resilient solutions. AI technologies provide a robust framework to meet these evolving demands by introducing predictive analytics, automation, real-time decision-making, and intelligent systems that work across various supply chain functions.

AI enables companies to optimize operations across procurement, production, inventory management, transportation, distribution, and customer service. As businesses seek to create leaner, more agile, and customer-centric supply chains, AI emerges as the enabler of this transformation. This article explores AI’s full potential in the logistics and supply chain ecosystem, examining core technologies, practical applications, implementation challenges, ethical implications, and future trends. In doing so, it presents a comprehensive 10,000-word overview that underscores how AI is not just enhancing supply chains but fundamentally redefining them.

The Evolving Landscape of Supply Chains

Modern supply chains are multi-tiered, data-intensive networks that span across continents. With the rise of e-commerce, just-in-time delivery expectations, and the need for operational transparency, organizations are compelled to digitize their logistics systems. The COVID-19 pandemic starkly exposed vulnerabilities in global supply chains, accelerating the urgency for AI-driven solutions that provide resilience and responsiveness. Today’s supply chain must be predictive rather than reactive, capable of anticipating disruptions and adjusting course instantly. This demands a level of intelligence, speed, and adaptability that traditional ERP and manual systems cannot offer.

AI plays a vital role in managing this complexity. Through advanced analytics, machine learning algorithms, and real-time data processing, AI systems provide actionable insights that support strategic and operational decision-making. The result is a supply chain that is not only efficient but also responsive and self-correcting in the face of unforeseen events.

Core AI Technologies Powering Supply Chain Transformation

The transformative power of AI in logistics and supply chains is derived from several core technologies:

- Machine Learning (ML): ML algorithms analyze massive datasets to uncover patterns, optimize operations, and forecast demand. These algorithms continuously improve as they learn from new data.

- Natural Language Processing (NLP): NLP is used to automate contract analysis, understand unstructured data, enhance chatbot interactions, and streamline procurement communications.

- Computer Vision: Utilized in visual inspection of products, inventory tracking, warehouse surveillance, and quality control to ensure operational excellence.

- Robotic Process Automation (RPA): RPA automates rule-based, repetitive tasks such as data entry, invoicing, and compliance reporting, freeing up human resources.

- Internet of Things (IoT): IoT sensors feed real-time data on equipment performance, inventory levels, and environmental conditions to AI systems, enabling dynamic decision-making.

- Digital Twins: Virtual replicas of supply chain components powered by AI to simulate different scenarios, optimize workflows, and identify bottlenecks.

AI for Demand Forecasting and Inventory Optimization

Accurate demand forecasting is critical for balancing supply and demand, minimizing inventory costs, and improving customer satisfaction. Traditional forecasting methods are often limited by their reliance on historical data and static models. AI enhances this process by incorporating a wide range of variables including market trends, customer behavior, economic indicators, social media sentiment, and even weather forecasts.

AI algorithms such as recurrent neural networks (RNNs), long short-term memory (LSTM) models, and regression trees are capable of capturing complex patterns and non-linear relationships in the data. The result is highly accurate and dynamic forecasts that empower organizations to make proactive decisions about production planning, inventory replenishment, and resource allocation.

Inventory optimization further benefits from AI by leveraging real-time insights to determine optimal stock levels, reorder points, and safety stock thresholds. AI systems can identify slow-moving and obsolete items, suggest optimal stocking strategies for different regions, and automate replenishment decisions. This not only reduces carrying costs but also prevents stockouts and overstocking.

Transportation and Logistics Optimization with AI

Transportation constitutes a significant portion of supply chain costs, and optimizing it is a priority for logistics managers. AI-powered systems use predictive analytics, geospatial data, and real-time information from GPS and traffic sensors to recommend the most efficient delivery routes. These systems also consider factors such as fuel prices, weather conditions, and delivery windows to ensure timely and cost-effective transportation.

Load planning is another area where AI excels. By analyzing shipment sizes, weights, delivery schedules, and carrier constraints, AI systems determine optimal loading strategies to maximize space utilization and reduce transportation expenses. Furthermore, AI enables predictive maintenance by analyzing sensor data from vehicles to detect early signs of wear and schedule repairs before breakdowns occur, thus reducing downtime and service disruptions.

AI is also integral to autonomous vehicles and drones, which are gradually entering the logistics sector. These technologies promise to enhance last-mile delivery, especially in urban and remote areas, by providing faster, more reliable, and contactless services.

Warehouse Automation and AI-Enabled Fulfillment Centers

Modern warehouses are becoming highly automated environments where AI orchestrates the movement of goods with minimal human intervention. AI-driven warehouse management systems (WMS) oversee inventory tracking, order picking, packing, sorting, and dispatching. They ensure that operations are executed efficiently by optimizing layout designs, minimizing travel time, and balancing workloads among staff and robots.

Robots equipped with computer vision and AI algorithms perform tasks such as shelf scanning, order picking, and inventory audits. Collaborative robots (cobots) work alongside human workers, enhancing productivity and safety. AI also plays a role in dynamic slotting, where products are continuously reallocated to different locations within the warehouse based on real-time demand and frequency of access.

Fulfillment centers powered by AI can adapt quickly to demand spikes, such as those experienced during holidays or flash sales. They use real-time data and machine learning models to allocate resources efficiently, forecast staffing needs, and manage inventory placement to reduce handling time and errors.

Enhancing Visibility and Traceability Across the Supply Chain

One of the biggest advantages AI brings to supply chain management is enhanced visibility. By aggregating and analyzing data from multiple sources—suppliers, manufacturers, logistics providers, and customers—AI provides end-to-end transparency into supply chain operations. This visibility enables early detection of disruptions, proactive mitigation strategies, and more accurate delivery timelines.

AI also supports traceability, which is critical for industries such as food, pharmaceuticals, and electronics. Through computer vision, RFID, barcoding, and blockchain integration, AI helps track the movement and status of goods across the supply chain. It ensures that products comply with regulatory requirements, prevents counterfeiting, and enables rapid response in case of recalls.

Real-time dashboards powered by AI deliver actionable insights to supply chain managers, highlighting potential risks, performance deviations, and opportunities for improvement. This empowers decision-makers to respond promptly and effectively to evolving situations.

AI in Procurement and Supplier Relationship Management

Procurement is becoming increasingly strategic, and AI is transforming how organizations manage supplier relationships and sourcing decisions. AI tools evaluate suppliers based on criteria such as delivery performance, quality scores, pricing trends, risk exposure, and ESG compliance. They also monitor news and social media to detect potential supplier disruptions or reputational risks.

NLP algorithms analyze contracts and identify clauses that may pose legal or financial risks. AI platforms also automate routine procurement tasks such as request for proposals (RFPs), quote comparisons, and invoice processing. This reduces procurement cycle times and enhances accuracy.

By integrating AI into supplier relationship management (SRM) systems, organizations can proactively manage supplier performance, identify opportunities for collaboration, and foster innovation in their supply networks.

Sustainable Supply Chains and Green Logistics with AI

Sustainability is a growing priority, and AI enables organizations to build environmentally responsible supply chains. AI models optimize transportation routes to reduce fuel consumption and carbon emissions. They also recommend packaging designs that minimize waste and enhance recyclability.

In manufacturing, AI monitors energy consumption, water usage, and emissions to identify inefficiencies and suggest improvements. AI systems can also evaluate suppliers based on their environmental performance and encourage greener sourcing practices.

Predictive analytics supports circular economy initiatives by identifying opportunities for product reuse, remanufacturing, and recycling. For example, AI can determine the most valuable recovery options for returned products and guide decisions on refurbishment, resale, or disposal.

Reverse Logistics and Returns Management

Reverse logistics is a critical but often neglected part of the supply chain. AI enhances returns management by predicting return rates, identifying root causes of returns, and optimizing reverse flows. Retailers can use AI to detect fraudulent returns, automate return authorizations, and provide personalized return policies.

AI also helps in asset recovery by determining the most cost-effective path for returned goods—whether to restock, repair, recycle, or dispose of them. This improves resource utilization, reduces waste, and enhances customer satisfaction.

Real-Time Decision-Making and Cognitive Supply Chains

Cognitive supply chains leverage AI to make real-time decisions based on complex and dynamic data inputs. AI systems continuously monitor internal and external variables—ranging from production delays and supplier risks to customer demand and geopolitical developments—and adjust operations accordingly.

For instance, if a shipment is delayed, AI can automatically reroute goods from another warehouse or prioritize production to meet demand. If demand surges unexpectedly, AI can activate alternative suppliers or adjust inventory buffers. This level of intelligence and responsiveness creates a resilient, adaptive, and customer-focused supply chain.

Improving Customer Experience Through AI

Customer expectations are higher than ever, and AI plays a pivotal role in delivering superior experiences. AI-driven recommendation engines personalize product offerings based on purchase history and preferences. Chatbots powered by NLP handle inquiries, process orders, and provide real-time updates on shipments.

AI systems enable precise delivery tracking, proactive communication, and flexible delivery options, enhancing customer trust and satisfaction. They also analyze customer feedback and returns data to identify pain points and drive continuous improvement.

Integrating AI with ERP and SCM Platforms

For AI to deliver its full potential, it must be integrated with enterprise systems such as ERP, WMS, TMS, and customer relationship management (CRM). This integration ensures seamless data flow and unified decision-making across departments. AI modules enhance these systems with predictive insights, automation, and intelligent workflows.

Cloud-based platforms facilitate scalability and collaboration, allowing global teams to access real-time information and coordinate actions. APIs and middleware enable interoperability between AI tools and legacy systems, preserving investments while enabling innovation.

Challenges to AI Adoption in Supply Chains

Despite its advantages, AI adoption in supply chains faces several challenges:

- High costs of implementation and maintenance

- Data quality and integration issues

- Resistance to change and lack of digital skills

- Difficulty in measuring ROI

- Ethical concerns and job displacement

Organizations must address these challenges through clear strategies, robust data governance, and change management programs. Collaboration with technology partners and investment in training and upskilling are also essential.

Ethical and Workforce Considerations

AI’s impact on jobs is a concern, especially in roles involving manual and repetitive tasks. While AI creates new roles in data science, AI governance, and system management, organizations must proactively support workforce transitions. Ethical AI practices demand transparency, fairness, and accountability. Companies must ensure that AI systems are free from bias, respect privacy, and align with societal values.

AI for SMEs in Logistics and Supply Chain

Small and medium-sized enterprises (SMEs) can also benefit from AI. Cloud-based AI tools provide affordable access to capabilities like demand forecasting, inventory management, and transportation optimization. Industry partnerships, open-source tools, and government support further reduce barriers to entry.

SMEs can leverage AI to compete more effectively by enhancing agility, reducing costs, and delivering differentiated customer experiences.

Case Studies and Industry Applications

Leading companies are showcasing the power of AI in logistics:

- Amazon uses AI for demand forecasting, robotic fulfillment, and dynamic routing.

- Walmart applies machine learning to optimize inventory and supply planning.

- Maersk leverages predictive analytics for fleet and container tracking.

- DHL uses AI to predict shipment volumes and optimize routes.

These examples illustrate how AI enhances efficiency, reduces costs, and strengthens resilience. Smaller firms are also achieving success through targeted AI implementations.

The Future of AI in Supply Chains

The future of AI in supply chains is bright. Emerging trends include:

- AI-powered digital twins for end-to-end simulation

- Generative AI for autonomous planning and scenario analysis

- Cognitive automation for hands-free decision-making

- Quantum computing for solving complex optimization problems

AI will drive the evolution of smart, autonomous, and sustainable supply chains that continuously learn, adapt, and innovate.

Conclusion

AI is a powerful enabler of supply chain excellence. By transforming forecasting, inventory, transportation, warehousing, procurement, and customer engagement, AI delivers significant improvements in efficiency, agility, and resilience. As organizations embrace digital transformation, AI will become integral to their competitive strategy. With the right vision, infrastructure, and ethical framework, AI has the potential to revolutionize global supply chains and create lasting value for businesses, customers, and society.